For taf, the Direct Relationship program is the basis of our consistency and our high quality. It is our core principle and it is based on personal relationship, mutual trust, honesty and respect, and it is built on the direct, personal contact with the people we work with.

Yiannis Taloumis visits the producers and farmers of the Taf Direct Relationship network annually, and during these visits he is always happy to discover ways for taf to support the local communities.

Fulfilling this commitment to our partners once again this year, taf is happy to support the local Boa Vista community with its wastewater transport and treatment system. A project that promotes sustainable cultivation and better management of resources with multiple benefits not only for the environment, but also for the people of the local community.

We are always pleased and honored to work closely with our partners and to create together!

Boa Vista Valley – Wastewater transport and treatment system

Project Execution:

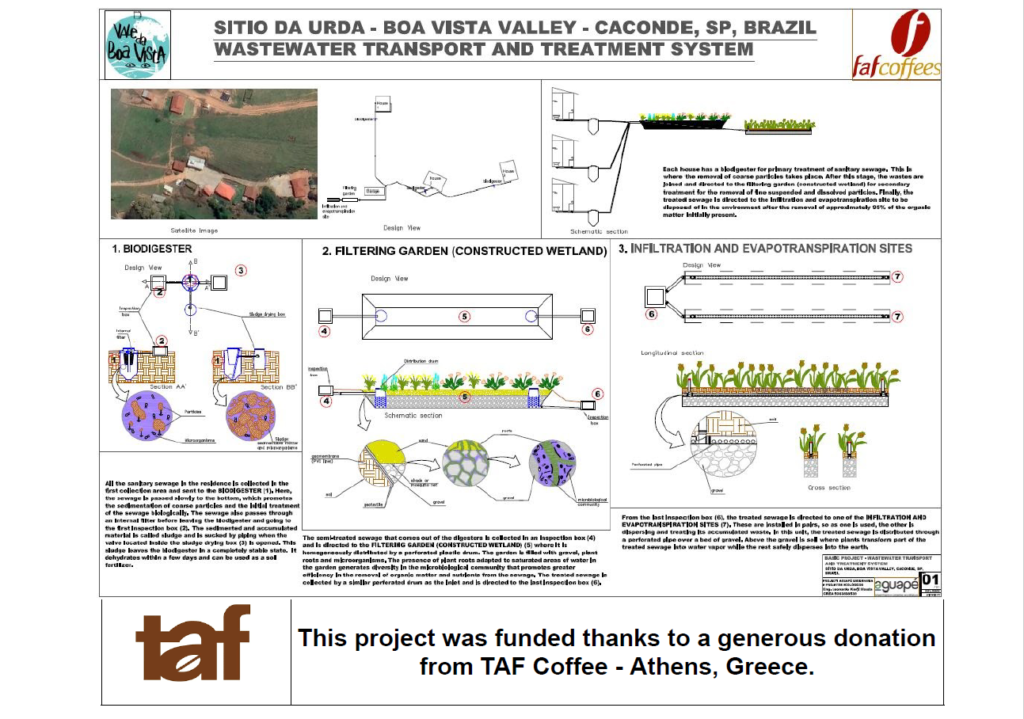

Each house has a biodigester for primary treatment of sanitary sewage. This is where the removal of coarse particles takes place. After this stage, the wastes are joined and directed to the filtering garden (constructed wetland) for secondary treatment for the removal of fine suspended and dissolved particles. Finally, the treated sewage is directed to the infiltration and evapotranspiration site to be disposed of in the environment after the removal of approximately 95% of the organic matter initially present.

Stage 1 – Biodigester

All the sanitary sewage in the residence is collected in the first collection area and sent to the biodigester (1). Here, the sewage is passed slowly to the bottom, which promotes the sedimentation of coarse particles and the initial treatment of the sewage biologically. The sewage also passes through an internal filter before leaving the biodigester and going to the first inspection box (2). The sedimented and accumulated material is called sludge and is sucked by piping when the valve located inside the sludge drying box (3) is opened. This sludge leaves the biodigester in a completely stable state. It dehydrates within a few days and can be used as a soll fertilizer.

Stage 2 – Filtering Garden (Constructed Wetland)

The semi-treated sewage that comes out of the digesters is collected in an inspection box (4) and is directed to the Filtering Garden (Constructed Wetland) (5) where it is homogeneously distributed by a perforated plastic drum. The garden is filled with gravel, plant roots and microorganisms. The presence of plant roots adapted to saturated areas of water in the garden generates diversity in the microbiological community that promotes greater efficiency in the removal of organic matter and nutrients from the sewage. The treated sewage is collected by a similar perforated drum as the inlet and is directed to the last inspection box (6).

Stage 3 – Infiltration and Evapotranspiration Sites

From the last inspection box (6), the treated sewage is directed to one of the infiltration and evapotranspiration sites (7). These are installed in pairs, so as one is used, the other is dispersing and treating its accumulated waste. In this unit, the treated sewage is distributed through a perforated pipe over a bed of gravel. Above the gravel is soll where plants transform part of the treated sewage into water vapor, while the rest safely disperses into earth.